Kmart Group - Human rights and ethical sourcing

Kmart Group acknowledges its responsibility to respect human rights and promote environmental sustainability within its supply chain. Stakeholders rightfully expect that the retail products sold across the Kmart Group retail network are not produced in a way that compromises the rights of workers or adversely impacts the environment of sourcing countries.

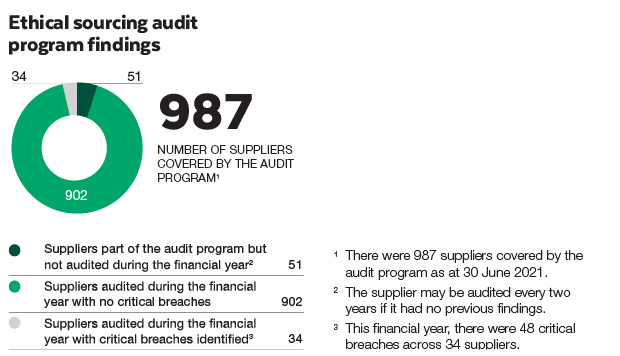

The complexity and depth of supply chains remains a key challenge for Kmart Group in its ethical sourcing (ES) and wider sustainability efforts. The Kmart Group Ethical Sourcing Program includes a detailed compliance framework designed to support suppliers to meet our ethical sourcing standards. Factory disclosures and third-party factory audits are central to the program. Where critical, major and other non-conformances are identified, corrective actions are implemented and improvements are monitored through follow-up audit. During the 2021 financial year, Kmart and Target continued their efforts to strengthen the Kmart Group Ethical Sourcing Program with a focus on improving modern slavery risk mitigation controls and improving transparency beyond finished goods manufacturers, further down the supply chain into processing facilities, component manufacturers and suppliers of raw materials.

Processes were also put in place at Catch to ensure suppliers of Catch own-brand products are integrated into the wider Kmart Group ES program.

Achievements in the 2021 financial year included:

- rolled out an updated Kmart Group ES Code and accompanying audit program, which incorporates new minimum standards to mitigate the risk of modern slavery further down Kmart Group supply chains. This included new standards requiring Kmart Group suppliers to ensure their own suppliers, or any third party providing raw materials, components, labour or services to the supplier, also comply with the standards of conduct outlined in the Code

- updated the Kmart Group Ethical Sourcing Audit Checklist with enhanced forced labour checkpoints. This was supported by Forced Labour training for internal Quality and Ethical sourcing team members conducted by a specialist firm.

- released a new Ethical Sourcing Program Supplier Manual to provide more detailed instructions around the procedures that underpin the ethical sourcing program

- adopted an Ethical Sourcing Transparency Policy setting out clear requirements under which Kmart Group suppliers, when requested, must disclose information about their supply chain. This includes information about any tier in the supply chain, including finished goods manufacturers, processing facilities, component manufacturers, down to suppliers of raw materials

- undertook supply chain mapping to identify Tier 2 and 3 facilities used by Kmart Group Asia Tier 1 Suppliers, which confirmed 544 Tier 2 and 3 facilities involved in the process of yarn (spinner), weaving, knitting, dyeing, printing, finishing or washing

- updated the Kmart and Target factory lists to start including Tier 2 and 3 facilities. The list now includes the Tier 2 and 3 processing facilities being used by the suppliers supplying over 50 per cent of Kmart Group own brand clothing, towel and bedding products. This percentage is based on order volumes in our apparel business in the past financial year.

- developed the process framework to integrate Catch own-brand suppliers into the Kmart Group Ethical Sourcing Program

- as part of Kmart Group’s public commitment to provide professional skills, health or education training to at least 100,000 women in our supply chain by December 2025, we launched the BSR HER+ program in seven factories in Bangladesh and two factories in Vietnam with the capacity to train up to 20,000 women. The COVID-19 pandemic created challenges around face-to-face training within the training program. To address this, a new App based toolkit was developed to facilitate remote training

- as part of Kmart Group’s public commitments in the area of Living Wage and Responsible Purchasing, considerable progress has been made, including:

- the development and implementation of a new open costing sheet with our team and suppliers to itemise and ring-fence labour costs

- continued roll-out of enhanced planning and forecasting mechanisms with strategic and core suppliers to improve accuracy of forecasts and maximise capacity planning in factories

- the development of a responsible exit strategy and procedures in accordance with the ACT Responsible Exit Policy and Checklist

- commenced implementation of the ACT purchasing practices baseline assessment with our team and suppliers.

COVID-19

The impact of COVID-19 continued to create challenges for suppliers this financial year, with flow on impacts for the Kmart Group Ethical Sourcing Program. In response to the second wave of COVID-19 in India, Bangladesh and Indonesia, the Kmart Group Ethical Sourcing team provided support to suppliers in those countries, via training webinars and sharing best practices, to assist in their efforts to comply with government COVID-safe workplace safety guidelines and to pay worker wages fully and on time.

Travel restrictions meant the Kmart Group Ethical Sourcing team was required to conduct virtual factory visits in place of normal face-to-face visits to verify basic labour compliance and COVID safety measures within supplier factories. Despite this, Kmart Group managed to maintain implementation of our normal third-party ethical sourcing audit procedures throughout the year.

Rollout of the BSR HER+ program’s face-to-face training was also delayed in Bangladesh, India and Indonesia. To address this, a new App based toolkit has been developed to facilitate remote training.